The 12th International Mining and Geological Forum MINEX Kazakhstan 2022 has concluded in Nur-Sultan

About MINEX Kazakhstan Forum

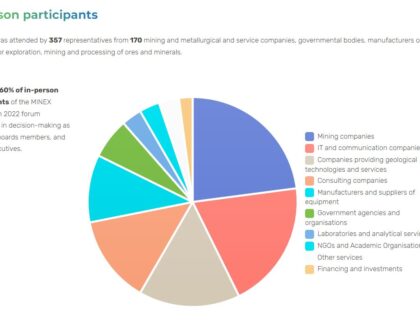

The 12th MINEX Kazakhstan Mining and Exploration Forum took place in the city of Nur-Sultan on 6-7 April 2022. The Forum was the first major international industry event organised after the lifting of COVID19 restrictions in Kazakhstan. Over 950 physical and remote participants from Kazakhstan and other countries participated in MINEX Kazakhstan 2022.

The Forum stimulated a broad discussion of the challenges, trends and initiatives taking place in the mining and geological industry in Kazakhstan. More than 80 heads and experts of the ministries, international organisations and industrial companies discussed the actions taken by the government and business to strengthen Kazakhstan’s ability to implement strategic economic priorities and increase the country’s participation in global production.

A Brief Overview of the Second Day of the Forum

Sixth session

In the morning of April 7, the forum continued its work with a session on the topic “Exploration – Resources for Growth and Efficiency“. The national project of Kazakhstan for the development of the geological exploration industry 2021-2025 proposes to increase the annual financing of geological prospecting work by about four times. The government is developing new mechanisms to stimulate the participation of national and international companies in the search for new deposits and the development of promising subsoil areas. Given the huge areas, the effectiveness of geological prospecting largely depends on the use of advanced technologies, comprehensive analysis and high competence of specialists.

At the session, presentations were made by specialists who presented advanced technologies and projects for the organization of geological exploration for the search for deposits.

Bakhytzhan Imazhanov, Director of the Department of Digital Transformation, Kazatomprom, presented to the forum participants the company’s experience in the development and implementation of a digital tool for determining the contour of ore bodies based on machine learning. Alexander Frolov, Client Solutions team lead at Seequent, spoke about improving the efficiency of junior companies in the light of today’s industry challenges. Presentation by Tim Archer, Managing Director of Reid Geophysics, was devoted to the use of modern geophysical technologies to reduce the risks of mineral exploration in Kazakhstan. Elvira Belousova, Geophysical Engineer from EM- SURVEYS spoke about the experience of mineral exploration based on innovative and adapted standards of geophysics of ground, air and underground basing. The expert focused on geophysical methods of search polymetallic and gold ore deposits. It is possible to minimize problems with the help of proper geophysics, the success of which lies in the use of innovative technologies for isolating useful signals from a search object against the background of numerous interferences and relying on physical and geological models of deposits. The methodology for assessing the prospects of territories for porphyry mineralization was the subject of a report by Sergey Petrov, Executive Director of LIMS. The report presented the results of the use of modern precision studies of the typomorphic features of accessory minerals of granitoid massifs, the patterns of distribution of chemical elements and minerals in rocks, aimed at identifying the prospects of territories for porphyry mineralization. In the presentation of the possibilities of modern high-precision magnetic exploration in the search for iron ores Madi Mahmuduly, the leading geophysicist of Aurora Minerals Group presented the results of the application of a complex of modern high-precision magnetic exploration and geological routes that allowed effective assess the extent of iron mineralization at one of the deposits in Central Kazakhstan. The presented model has a number of conventions, but is an example of the effective application of modern geophysics to calculate the economic model at an early stage of the study of iron ore objects. The session ended with a report by Yuri Davydenko, Executive Director of the Siberian School of Geosciences of IRNITU, in which he presented a study of geophysical methods of porphyry systems of Kazakhstan. In the course of the research, problems were successfully solved using the technology of electromagnetic sensing and induced polarization (EMZ-VP) in combination with unmanned geophysical technologies.

Seventh session

After the break, a session was held on the use of “Clean” technologies and strategies for the sustainable development of mining and metallurgical enterprises. The session was organised with the support of the Department for International Trade of Great Britain.

Environmental, social and governance requirements for the mining and metallurgical industry are becoming more stringent and large-scale. This is facilitated by the decarbonization of the world economy and the implementation of the UN Sustainable Development Goals. Realizing this, many mining enterprises in Kazakhstan are revising their sustainable development strategies and actively introducing technologies and projects that contribute to reducing environmental impact, reducing emissions and waste and the efficient use of energy and water resources.

At the session, British technologies proposed for use in the mining and metallurgical industry were presented. Kevin Porter, Commercial Director of Terra Motion, spoke about the use of InSAR technology to monitor soil movement in the mining industry. Using this method, the company can predict the collapse of tailings dams, monitor the level of contaminated water, prevent environmental disasters, and support asset management and risk assessment in a cost-effective way.

Robert Pell, Founder and CEO of Minviro, introduced a new mineLCA technology that allows you to collect real-time data on the environmental impact of products produced by mines, refineries and refineries. Johan Kempe, Business Development Manager at Howden spoke about innovations in mine ventilation equipment. The company has conducted several case studies on how mining companies can find opportunities to reduce operating costs and associated greenhouse gas emissions while maintaining clean air and good working conditions in the mines. Ildar Yamaliev, General Director of Concret Kanvas, gave examples of the use of Concrete Canvas in the mining industry in the CIS countries and around the world. Irek Amirov, Deputy Commercial Director of Aggreko Eurasia, concluded the session with a presentation of effective rental solutions for power generation.

Mining Goes Digital Conference

After a short break, the Mining Goes Digital Conference dedicated to the digital transformation of mining and metallurgical enterprises in Kazakhstan started at the forum.

Eighth session

The conference was opened by a session on the topic “Digital Mine. Overview of Solutions for the Mining“, organized in partnership with AVEVA.

The mining industry plays a crucial role in our lives. Today, the world is witnessing a significant increase in world consumption of commodities, driven by trends such as urbanization and industrialization. These growing needs will continue to drive the industry over the years. Thanks to digital transformation, mining enterprises receive intelligent and reliable tools for analytics, asset and business process management, creating data infrastructure, increasing transparency and efficiency of operations throughout the value chain. During the session, AVEVA and Kazakhstani enterprise experts spoke about the most relevant solutions for the mining sector, and key customers shared their success stories and case studies.

Roman Sidorin, Key Account Manager, AVEVA, gave a talk on “PI System: Data Infrastructure as the Basis for the Digitalization of Manufacturing,” in which he presented the capabilities and benefits of the real-time data infrastructure used by more than 80% of the largest mining and metals companies in 87 countries. Sergey Mashin, Business Development Director, AVEVA spoke about the experience of optimising the value chain from the field to the port. Implementing a single decision-making tool at all stages of supply and demand generation ensures that every part of the mining operations contains sufficient analytics and data. This approach increases the transparency and efficiency of operations. Key benefits also include increased productivity, reduced downtime, eliminate unnecessary operations, efficient energy consumption, and ample opportunity to innovate throughout. the value chain from the mine to the port. Andrey Lozhnikov, Deputy Director of the Industrial Complex “Kazzinc-Avtomatika” presented a project for the modernization of the Unified Information Platform for Data PI System and integration with the ERP system of Enterprises of Kazzinc. Adilet Mukhitov, Leading Engineer of the Digital Transformation Department of JSC “Ust-Kamenogorsk Titanium-Magnesium Plant”, presented a case of implementation of the MES-system in the workshops for the production of magnesium and spongy titanium. The plant began the introduction of PI System in 2020. To date, on the basis of PI System, the Production Control System and the Subsystem for Calculating Key Production Performance Indicators have been implemented in the main workshops for the production of magnesium and titanium sponge. AVEVA PI System technology has proven to be effective in providing management with operational, reliable data on the current state of production. In the near future, it is planned to implement AVEVA PI System in other main and auxiliary workshops of the plant.

Ninth session

The next session of the Mining Goes Digital conference was organised under the theme ” Digital transformation of mining enterprises in Kazakhstan – new projects and opportunities“.

Industrial digitalisation is one of the top drivers of the economic development of Kazakhstan. According to official estimates, virtually all mining operations in the country have a 10-15 percent potential to improve efficiency and reduce the cost of operations. At the small and medium-sized enterprises, this potential is 50% or greater. Many mining companies have developed digital transformation strategies and are exploring the possibilities of introducing 4.0 technologies to improve the efficiency of individual productions and supply chains. Digital technologies enable to streamline business processes and increase the overall return on investment. There are many areas for the use of digital technologies, however, the maximum effect can be achieved only in the case of a comprehensive implementation of information systems – a complete digital transformation of the individual companies and the whole industry.

The session was opened by Sergey Tsvetkov, Senior Business Development Manager of Wonderware Russia & CIS. In his speech, he gave an overview of successful production management projects in the mining and metallurgical industry based on Wonderware / AVEVA software products. Assemgul Imantayeva, Head of the Geological Modeling Department, KATKO, spoke about the creation and use of a 3D geological model to assess uranium reserves and resources for verification and approval of the design of operational units, as well as for further hydrodynamic modeling. Marcin Kushtal, CEE and CIS Sales Director, Rajant Corporation, spoke about the challenges of improving operational efficiency using the Rajant (InstaMesh)+WiFi+LTE hybrid communication network. Nikolay Kamensky General Director of Two Key spoke about the experience of digitisation of Kazakhstani mining enterprises using the 3DEXPERIENCE platform. Alexander Dzigalyuk, Head of Business Unit Micromine Pitram of MICROMINE Central Asia, demonstrated on the example of implemented cases a comprehensive software solution for managing a mining enterprise, including registration, management and processing of enterprise data in real-time. The speakers were remotely joined by Mikhail Nazarenko, CEO and co-founder of K-MINE. He spoke about the experience of a comprehensive digital transformation of the processes of management and engineering support of mining operations on the example of Kostanay Minerals JSC, the leading manufacturer The use of a digital solution made it possible to improve the accuracy of volume calculations and accounting of the movement of production reserves based on the created 3D digital model; accelerate the calculation of the main technical indicators of the plan, analyze several options and determine the optimal cost, thus increasing profits; simulate safety zones when creating a drilling project taking into account the actual situation mining operations; to increase the safety of mining operations and, in general, to reach a new level of management.

Еenth Session

Today, virtually all IT companies offer digital solutions that promise to increase productivity, increase profits, and increase planning efficiency. The question is, will the results from innovation meet customer expectations? Which solutions will really contribute to growth in a single production with its unique specifics, and which will lead to unjustified costs? The successful experience of using digital products, as well as their compatibility and resistance to cyber risks, play an important role in the selection of proposals.

At the final session of the Mining Goes Digital conference, proven digital solutions and technologies for improving the productivity of mining and metallurgical enterprises were discussed. Victor Portnov, Product Director of Conundrum Industrial, shared his experience in optimizing production processes in processing plants using artificial intelligence. Andrey Tyan, Director of IntelliSense – LAB, spoke about the optimization of the production processes of “Pustynnoe” plant of the company Altynalmas with the help of artificial intelligence applications. The application increased processing productivity by reducing overloads, reducing mill downtime caused by unscheduled shutdowns and stabilizing the grinding process. Expected benefits: increased recovery and increased process transparency. As part of his report, Levon Kirakosyan, CEO of Intelligent Solutions, spoke about the practical application of technologies based on artificial intelligence in the study and description of the drilling core. He shared the existing practices and developments in the automation of the determined geological and geomechanical characteristics and spoke about the possibilities of using hyperspectral cameras. Rafal Valecki, Head of Strategic Projects from Datamine, spoke about the use of sales and logistics tools in managing the sales processes of finished products of mining and metallurgical enterprises. Evgeny Lyubavin, Director of LocoTech-Signal Asia, concluded the session with a presentation of a complex of systems based on machine vision to improve the safety of industrial transport. Machine vision allows you to improve the performance of vehicle management due to advanced infrastructure diagnostics. On the basis of the company “LocoTech-Signal” was created a Competence Center for Machine Vision in the field of tasks of railway transport. Using the example of real cases, he spoke about how the digital solution using artificial intelligence allows you to remotely control locomotives with minimal human participation. In particular, the technology provides reliable monitoring of the condition and actions of the driver, energy-efficient control of the movement of the locomotive itself, and also helps to detect obstacles. to prevent collisions.

Business Track

In parallel with the forum, a business track was held at the exhibition site on the topic “ Digital technologies for improving the efficiency of mining and geological prospecting”. It presented the complex automation of planning and accounting at mining enterprises based on the solutions “1C: Enterprise” of the company “Synergo Soft Systems“; DMMS – a universal digital platform for monitoring and managing all production cycles from AG TECH; Digital solutions from mine to factory for safe productive operation of WEIR Motion Metrics; Experience of LABVEA in the implementation of LabWare LIMS in the laboratories of the metallurgical industry; Digital mine according to the methodology from SightPower.

MineDigital Competition

During the day, the forum participants determined the winners of the digital transformation technology competition – MineDigital Kazakhstan. To collect votes, an algorithm built into the mobile application of the forum was used. This technology allows you to build a rating of presentations in real time, collecting votes from both face-to-face participants in Nur-Sultan and participants present online. The announcement of the results of the competition took place at the final gala dinner of the forum. The participants of the competition received commemorative diplomas. Presentations that received the maximum number of votes were awarded prizes for the first, second and third places.

Post-Event Materials

Presentations presented at the forum, video recordings of the forum sessions, the Mining Goes Digital conference and business tracks will be published on April 25. Access to the materials will be provided to all delegates of the forum.

Related Posts

April 15, 2022

MINEX Kazakhstan’22 Forum summary

April 7, 2022