MINEX Kazakhstan 2022

The 12th MINEX Kazakhstan Mining and Exploration Forum took place in the city of Nur-Sultan on 6-7 April 2022

Briefly about previous events

The MINEX Forum has been held in Kazakhstan since 2010 and is one of the most influential mining events in Central Asia. Annually the Forum brings together leaders from the national and international mining and exploration companies, ministries and other governmental organisations, investment funds and banks, service companies and equipment manufacturers from Kazakhstan and overseas.

The last time forum MINEX Kazakhstan was held in a physical format in 2019 and brought together more than 450 executives from 16 countries representing 152 companies and organisations. More than 600 people visited the trade show, and more than 80 experts spoke at the Forum. In March 2021, a virtual 3D exhibition was launched on the digital platform of the Forum. The exhibition was created in an interactive format using virtual reality, artificial intelligence, and online communication technologies. In September 2021 the 11th MINEX Kazakhstan Forum was held online bringing to its remote platform over 700 participants from Kazakhstan and abroad.

MINEX Kazakhstan 2022 summary

The 12th MINEX Kazakhstan Mining and Exploration Forum took place in the city of Nur-Sultan on 6-7 April 2022. The Forum was the first major international industry event organised after the lifting of COVID19 restrictions in Kazakhstan. Over 950 physical and remote participants from Kazakhstan and other countries took part.

The Forum stimulated a broad discussion of the challenges, trends and initiatives taking place in the mining and geological industry in Kazakhstan. More than 80 heads and experts of the ministries, international organisations, mining and industrial companies discussed the actions taken by the government and business to strengthen Kazakhstan’s ability to implement strategic economic priorities and increase the country’s participation in the global production of critical metals and materials.

New trade, investment and business development opportunities in the mining and exploration of mineral resources in Kazakhstan and the countries of Central Asia were presented at the Forum. National and international companies, stock exchanges and institutional investors participated in the discussions on the prospects and challenges for organising finance and attracting investors in mining and carbon zero modernisation projects.

At the technical sessions of the Forum, Kazakhstani and International companies presented cases and technologies in various practical areas e.g. design of the digital mine twins, transition to renewable energy sources, decarbonisation of production, environmental monitoring, industrial safety, financing ESG projects, closure of deposits and reclamation of subsoil use facilities.

Mining Goes Digital Conference

The Mining Goes Digital conference was organised for the first time at the Forum in Kazakhstan. The conference was dedicated to the digital transformation of mining and metallurgical enterprises in Kazakhstan and showcased digitalisation examples at Ust-Kamenogorsk Titanium and Magnesium Plant, KATKO, Kostanay Minerals, National Atomic Company Kazatomprom, Kazzinc and ZIF “Pustynnoe” at Altynalmas.

Trade show

One of the important components of the Forum is the presentation of innovative mining and exploration technologies. Over 40 Kazakhstani and International companies demonstrated their products and achievements at the exhibition organised during the Forum. 16 companies from Kazakhstan, Russia, Great Britain and Canada held demonstrations of innovative technologies and equipment at the business tracks.

MineDigital Competition

Digitalisation of industrial production is one of the priorities of Kazakhstan’s economic development. According to official estimates, digitalisation can increase the efficiency of almost all enterprises of the mining and metallurgical industry and reduce the cost of mining transportation operations by 10-15 percent. In small and medium-sized enterprises, this potential is up to 50% or more. Many mining and metals companies have already formed a strategy for the digital transformation of production and are studying the possibilities of introducing Industry 4.0 technologies to improve the efficiency of both individual production facilities and large integrated complexes.

The first MineDigital Competition was organised alongside the Forum and provided an independent platform for evaluating the real prospects of implementation of advanced digitalisaiton technologies at the mining and metals enterprises in the Republic of Kazakhstan.

All participants received commemorative diplomas. Presentations that received the highest number of votes were awarded prizes for the first, second, and third places. The awards ceremony took place at the Gala Dinner which concluded the Forum.

MINEX Kazakhstan 2022 facts and figures

In-person participants

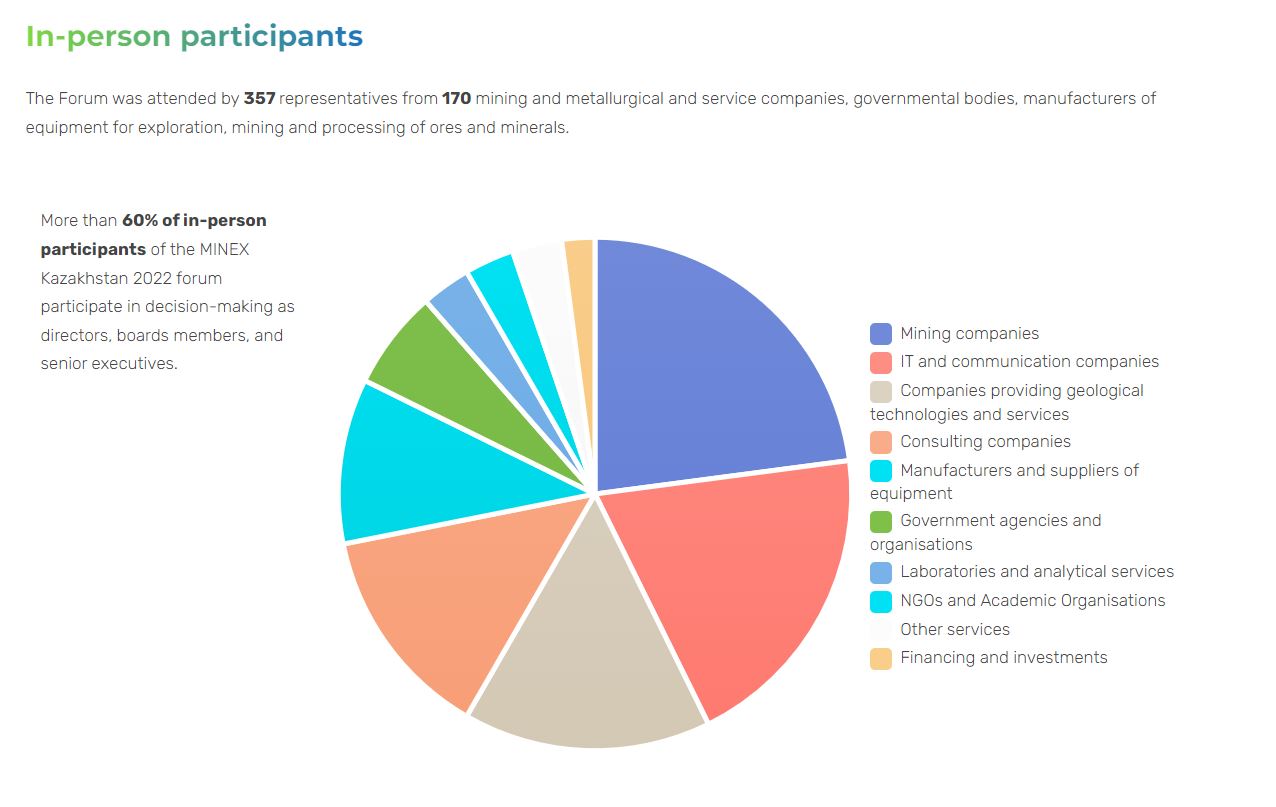

The Forum was attended by 357 representatives from 170 mining and metallurgical and service companies, governmental bodies, manufacturers of equipment for exploration, mining and processing of ores and minerals.

More than 60% of in-person participants of the MINEX Kazakhstan 2022 forum participate in decision-making as directors, boards members, and senior executives.

- Mining companies

- IT and communication companies

- Companies providing geological technologies and services

- Consulting companies

- Manufacturers and suppliers of equipment

- Government agencies and organisations

- Laboratories and analytical services

- NGOs and Academic Organisations

- Other services

- Financing and investments

Geographical location of in-person participants

16 countries were represented at the forum in Nur-Sultan. More than half of the in-person participants of the forum live and work in Kazakhstan. Besides the local companies, the largest groups of participants were from Russia, the United Kingdom, and Turkey.

- %

Remote participants

The live broadcast of the main sessions of the Forum was watched by 319 viewers. More than half connected from Kazakhstan, 20% from Russia and 8% from the UK. The rest of the viewers were from Afghanistan, Australia, Azerbaijan, Bahrain, Bulgaria, Canada, Finland, Georgia, Germany, Mongolia, Norway, South Africa, Spain, Switzerland, Ukraine, the United States and Uzbekistan.

Exhibiting companies

48 companies and organisations from Kazakhstan, Russia, Great Britain, Australia, the USA, Germany, New Zealand and Canada presented at the exhibition, held within the framework of the Forum. Several companies from Ukraine and Canada were represented only in the virtual section of the exhibition.

About a third of exhibiting companies specialize in the production and supply of equipment for geological prospecting, extraction, processing and transportation of metals and minerals. The second-largest group of companies specialise in digitalisation and automation of production in the mining and metallurgical industry. The third-largest group of exhibitors provide services and equipment for mineral exploration, drilling and blasting operations.

- Equipment

- IT and mobile communication

- Exploration services

- Consulting

- Engineering & Production

Exhibition Visitors

- %

263 in-person visitors were registered at the exhibition. As admission to the exhibition did not require pre-registration, the number of visitors was higher and is estimated at about 400-500 people.

Most of the registered visitors work at Kazakhstani and International mining and metallurgical enterprises, Equipment suppliers and Service sectors. The rest of the visitors work in government organisations, Universities, IT, Financial and Trading companies. The exhibition was also visited by foreign specialists from Iran, Croatia, Kyrgyzstan, Belarus, Canada, South Africa, the USA, Switzerland, and Uzbekistan.

Digitalisation of industrial production is one of the priorities of Kazakhstan’s economic development. According to official estimates, the digitalisation can increase the efficiency of almost all enterprises of the mining and metallurgical industry and reduce the cost of mining transportation operations by 10-15 percent. In small and medium-sized enterprises, this potential is up to 50% or more. Many mining and metals companies have already formed a strategy for the digital transformation of production and are studying the possibilities of introducing Industry 4.0 technologies to improve the efficiency of both individual production facilities and large integrated complexes.

The first competition of mining digital transformation technologies in the Republic of Kazakhstan.

MineDigital competition creates an international stage for the presentation of advanced technologies of mining automation and digital transformation. It also provides an independent platform for evaluating the real prospects of implementation of presented technologies at the mining and metals enterprises in the Republic of Kazakhstan.

The nature of the competition determines the use of a digital application for selecting the winners. All participants of the MINEX Kazakhstan 2022 Forum will have access to a mobile application that features the list of the presentations. During the sessions of the Mining Goes Digital conference and the Mining Digitalisation Business track organised on 7 April, the Forum participants will be invited to vote for the presentations they like most. More than 300 forum participants were invited to vote.

All participants of the competition will receive commemorative diplomas. Presentations that receive the maximum number of votes will be awarded prizes for the first, second, and third places.

First Place

The first place was taken by the presentation “Modernization of the Unified Information Platform for Data PI System. Integration with the ERP system of the enterprise”, presented by Andrey Lozhnikov, Deputy Director of the industrial complex “Kazzinc-Avtomatika” of the company Kazzinc. The modernization carried out on AVEVA technology provided an effective solution to the complex of production tasks for the centralization of PI System services in Kazzinc, accounting for equipment downtime, the integration of PI System and SAP PM, and the provision of cybersecurity levels.

Second Place

The second place went to the project “From Mine to Port: Value Chain Optimization”, presented by Sergey Mashin, Director of Business Development at AVEVA. This approach improves the transparency and efficiency of operations. Key benefits also include increased productivity, reduced downtime, elimination of redundant operations, efficient energy consumption, and ample opportunity for innovation along the entire value chain, from mine to port.

Third Place

The third place was taken by the presentation “Optimization of production processes of the plant “Pustynnoye” by ” AK Altynalmas” using artificial intelligence applications” by IntelliSense – LAB, presented by the Director Andrey Tyan. The IntelliSense team optimizes the grinding and flotation cycles at the Pustynoye mill. The grinding cycle optimization application allowed the customer to increase processing productivity by reducing overloads, reduce mill downtime caused by unscheduled shutdowns and stabilising the grinding process. A flotation cycle optimization application is under implementation. Expected Benefits: Improved recovery and improved transparency of the process.

We congratulate the winners and wish all the participants of the competition success in improving the efficiency and safety of enterprises of the mining and metallurgical complex of Kazakhstan.

About MINEX Kazakhstan Forum

The 12th MINEX Kazakhstan Mining and Exploration Forum took place in the city of Nur-Sultan on 6-7 April 2022. The Forum was the first major international industry event organised after the lifting of COVID19 restrictions in Kazakhstan. Over 950 physical and remote participants from Kazakhstan and other countries participated in MINEX Kazakhstan 2022.

The Forum stimulated a broad discussion of the challenges, trends and initiatives taking place in the mining and geological industry in Kazakhstan. More than 80 heads and experts of the ministries, international organisations and industrial companies discussed the actions taken by the government and business to strengthen Kazakhstan’s ability to implement strategic economic priorities and increase the country’s participation in global production.

A Brief Overview of the Second Day of the Forum

Sixth session

In the morning of April 7, the forum continued its work with a session on the topic “Exploration – Resources for Growth and Efficiency“. The national project of Kazakhstan for the development of the geological exploration industry 2021-2025 proposes to increase the annual financing of geological prospecting work by about four times. The government is developing new mechanisms to stimulate the participation of national and international companies in the search for new deposits and the development of promising subsoil areas. Given the huge areas, the effectiveness of geological prospecting largely depends on the use of advanced technologies, comprehensive analysis and high competence of specialists.

At the session, presentations were made by specialists who presented advanced technologies and projects for the organization of geological exploration for the search for deposits.

Bakhytzhan Imazhanov, Director of the Department of Digital Transformation, Kazatomprom, presented to the forum participants the company’s experience in the development and implementation of a digital tool for determining the contour of ore bodies based on machine learning. Alexander Frolov, Client Solutions team lead at Seequent, spoke about improving the efficiency of junior companies in the light of today’s industry challenges. Presentation by Tim Archer, Managing Director of Reid Geophysics, was devoted to the use of modern geophysical technologies to reduce the risks of mineral exploration in Kazakhstan. Elvira Belousova, Geophysical Engineer from EM- SURVEYS spoke about the experience of mineral exploration based on innovative and adapted standards of geophysics of ground, air and underground basing. The expert focused on geophysical methods of search polymetallic and gold ore deposits. It is possible to minimize problems with the help of proper geophysics, the success of which lies in the use of innovative technologies for isolating useful signals from a search object against the background of numerous interferences and relying on physical and geological models of deposits. The methodology for assessing the prospects of territories for porphyry mineralization was the subject of a report by Sergey Petrov, Executive Director of LIMS. The report presented the results of the use of modern precision studies of the typomorphic features of accessory minerals of granitoid massifs, the patterns of distribution of chemical elements and minerals in rocks, aimed at identifying the prospects of territories for porphyry mineralization. In the presentation of the possibilities of modern high-precision magnetic exploration in the search for iron ores Madi Mahmuduly, the leading geophysicist of Aurora Minerals Group presented the results of the application of a complex of modern high-precision magnetic exploration and geological routes that allowed effective assess the extent of iron mineralization at one of the deposits in Central Kazakhstan. The presented model has a number of conventions, but is an example of the effective application of modern geophysics to calculate the economic model at an early stage of the study of iron ore objects. The session ended with a report by Yuri Davydenko, Executive Director of the Siberian School of Geosciences of IRNITU, in which he presented a study of geophysical methods of porphyry systems of Kazakhstan. In the course of the research, problems were successfully solved using the technology of electromagnetic sensing and induced polarization (EMZ-VP) in combination with unmanned geophysical technologies.

Seventh session

After the break, a session was held on the use of “Clean” technologies and strategies for the sustainable development of mining and metallurgical enterprises. The session was organised with the support of the Department for International Trade of Great Britain.

Environmental, social and governance requirements for the mining and metallurgical industry are becoming more stringent and large-scale. This is facilitated by the decarbonization of the world economy and the implementation of the UN Sustainable Development Goals. Realizing this, many mining enterprises in Kazakhstan are revising their sustainable development strategies and actively introducing technologies and projects that contribute to reducing environmental impact, reducing emissions and waste and the efficient use of energy and water resources.

At the session, British technologies proposed for use in the mining and metallurgical industry were presented. Kevin Porter, Commercial Director of Terra Motion, spoke about the use of InSAR technology to monitor soil movement in the mining industry. Using this method, the company can predict the collapse of tailings dams, monitor the level of contaminated water, prevent environmental disasters, and support asset management and risk assessment in a cost-effective way.

Robert Pell, Founder and CEO of Minviro, introduced a new mineLCA technology that allows you to collect real-time data on the environmental impact of products produced by mines, refineries and refineries. Johan Kempe, Business Development Manager at Howden spoke about innovations in mine ventilation equipment. The company has conducted several case studies on how mining companies can find opportunities to reduce operating costs and associated greenhouse gas emissions while maintaining clean air and good working conditions in the mines. Ildar Yamaliev, General Director of Concret Kanvas, gave examples of the use of Concrete Canvas in the mining industry in the CIS countries and around the world. Irek Amirov, Deputy Commercial Director of Aggreko Eurasia, concluded the session with a presentation of effective rental solutions for power generation.

Mining Goes Digital Conference

After a short break, the Mining Goes Digital Conference dedicated to the digital transformation of mining and metallurgical enterprises in Kazakhstan started at the forum.

Eighth session

The conference was opened by a session on the topic “Digital Mine. Overview of Solutions for the Mining“, organized in partnership with AVEVA.

The mining industry plays a crucial role in our lives. Today, the world is witnessing a significant increase in world consumption of commodities, driven by trends such as urbanization and industrialization. These growing needs will continue to drive the industry over the years. Thanks to digital transformation, mining enterprises receive intelligent and reliable tools for analytics, asset and business process management, creating data infrastructure, increasing transparency and efficiency of operations throughout the value chain. During the session, AVEVA and Kazakhstani enterprise experts spoke about the most relevant solutions for the mining sector, and key customers shared their success stories and case studies.

Roman Sidorin, Key Account Manager, AVEVA, gave a talk on “PI System: Data Infrastructure as the Basis for the Digitalization of Manufacturing,” in which he presented the capabilities and benefits of the real-time data infrastructure used by more than 80% of the largest mining and metals companies in 87 countries. Sergey Mashin, Business Development Director, AVEVA spoke about the experience of optimising the value chain from the field to the port. Implementing a single decision-making tool at all stages of supply and demand generation ensures that every part of the mining operations contains sufficient analytics and data. This approach increases the transparency and efficiency of operations. Key benefits also include increased productivity, reduced downtime, eliminate unnecessary operations, efficient energy consumption, and ample opportunity to innovate throughout. the value chain from the mine to the port. Andrey Lozhnikov, Deputy Director of the Industrial Complex “Kazzinc-Avtomatika” presented a project for the modernization of the Unified Information Platform for Data PI System and integration with the ERP system of Enterprises of Kazzinc. Adilet Mukhitov, Leading Engineer of the Digital Transformation Department of JSC “Ust-Kamenogorsk Titanium-Magnesium Plant”, presented a case of implementation of the MES-system in the workshops for the production of magnesium and spongy titanium. The plant began the introduction of PI System in 2020. To date, on the basis of PI System, the Production Control System and the Subsystem for Calculating Key Production Performance Indicators have been implemented in the main workshops for the production of magnesium and titanium sponge. AVEVA PI System technology has proven to be effective in providing management with operational, reliable data on the current state of production. In the near future, it is planned to implement AVEVA PI System in other main and auxiliary workshops of the plant.

Ninth session

The next session of the Mining Goes Digital conference was organised under the theme ” Digital transformation of mining enterprises in Kazakhstan – new projects and opportunities“.

Industrial digitalisation is one of the top drivers of the economic development of Kazakhstan. According to official estimates, virtually all mining operations in the country have a 10-15 percent potential to improve efficiency and reduce the cost of operations. At the small and medium-sized enterprises, this potential is 50% or greater. Many mining companies have developed digital transformation strategies and are exploring the possibilities of introducing 4.0 technologies to improve the efficiency of individual productions and supply chains. Digital technologies enable to streamline business processes and increase the overall return on investment. There are many areas for the use of digital technologies, however, the maximum effect can be achieved only in the case of a comprehensive implementation of information systems – a complete digital transformation of the individual companies and the whole industry.

The session was opened by Sergey Tsvetkov, Senior Business Development Manager of Wonderware Russia & CIS. In his speech, he gave an overview of successful production management projects in the mining and metallurgical industry based on Wonderware / AVEVA software products. Assemgul Imantayeva, Head of the Geological Modeling Department, KATKO, spoke about the creation and use of a 3D geological model to assess uranium reserves and resources for verification and approval of the design of operational units, as well as for further hydrodynamic modeling. Marcin Kushtal, CEE and CIS Sales Director, Rajant Corporation, spoke about the challenges of improving operational efficiency using the Rajant (InstaMesh)+WiFi+LTE hybrid communication network. Nikolay Kamensky General Director of Two Key spoke about the experience of digitisation of Kazakhstani mining enterprises using the 3DEXPERIENCE platform. Alexander Dzigalyuk, Head of Business Unit Micromine Pitram of MICROMINE Central Asia, demonstrated on the example of implemented cases a comprehensive software solution for managing a mining enterprise, including registration, management and processing of enterprise data in real-time. The speakers were remotely joined by Mikhail Nazarenko, CEO and co-founder of K-MINE. He spoke about the experience of a comprehensive digital transformation of the processes of management and engineering support of mining operations on the example of Kostanay Minerals JSC, the leading manufacturer The use of a digital solution made it possible to improve the accuracy of volume calculations and accounting of the movement of production reserves based on the created 3D digital model; accelerate the calculation of the main technical indicators of the plan, analyze several options and determine the optimal cost, thus increasing profits; simulate safety zones when creating a drilling project taking into account the actual situation mining operations; to increase the safety of mining operations and, in general, to reach a new level of management.

Еenth Session

Today, virtually all IT companies offer digital solutions that promise to increase productivity, increase profits, and increase planning efficiency. The question is, will the results from innovation meet customer expectations? Which solutions will really contribute to growth in a single production with its unique specifics, and which will lead to unjustified costs? The successful experience of using digital products, as well as their compatibility and resistance to cyber risks, play an important role in the selection of proposals.

At the final session of the Mining Goes Digital conference, proven digital solutions and technologies for improving the productivity of mining and metallurgical enterprises were discussed. Victor Portnov, Product Director of Conundrum Industrial, shared his experience in optimizing production processes in processing plants using artificial intelligence. Andrey Tyan, Director of IntelliSense – LAB, spoke about the optimization of the production processes of “Pustynnoe” plant of the company Altynalmas with the help of artificial intelligence applications. The application increased processing productivity by reducing overloads, reducing mill downtime caused by unscheduled shutdowns and stabilizing the grinding process. Expected benefits: increased recovery and increased process transparency. As part of his report, Levon Kirakosyan, CEO of Intelligent Solutions, spoke about the practical application of technologies based on artificial intelligence in the study and description of the drilling core. He shared the existing practices and developments in the automation of the determined geological and geomechanical characteristics and spoke about the possibilities of using hyperspectral cameras. Rafal Valecki, Head of Strategic Projects from Datamine, spoke about the use of sales and logistics tools in managing the sales processes of finished products of mining and metallurgical enterprises. Evgeny Lyubavin, Director of LocoTech-Signal Asia, concluded the session with a presentation of a complex of systems based on machine vision to improve the safety of industrial transport. Machine vision allows you to improve the performance of vehicle management due to advanced infrastructure diagnostics. On the basis of the company “LocoTech-Signal” was created a Competence Center for Machine Vision in the field of tasks of railway transport. Using the example of real cases, he spoke about how the digital solution using artificial intelligence allows you to remotely control locomotives with minimal human participation. In particular, the technology provides reliable monitoring of the condition and actions of the driver, energy-efficient control of the movement of the locomotive itself, and also helps to detect obstacles. to prevent collisions.

Business Track

In parallel with the forum, a business track was held at the exhibition site on the topic “ Digital technologies for improving the efficiency of mining and geological prospecting”. It presented the complex automation of planning and accounting at mining enterprises based on the solutions “1C: Enterprise” of the company “Synergo Soft Systems“; DMMS – a universal digital platform for monitoring and managing all production cycles from AG TECH; Digital solutions from mine to factory for safe productive operation of WEIR Motion Metrics; Experience of LABVEA in the implementation of LabWare LIMS in the laboratories of the metallurgical industry; Digital mine according to the methodology from SightPower.

MineDigital Competition

During the day, the forum participants determined the winners of the digital transformation technology competition – MineDigital Kazakhstan. To collect votes, an algorithm built into the mobile application of the forum was used. This technology allows you to build a rating of presentations in real time, collecting votes from both face-to-face participants in Nur-Sultan and participants present online. The announcement of the results of the competition took place at the final gala dinner of the forum. The participants of the competition received commemorative diplomas. Presentations that received the maximum number of votes were awarded prizes for the first, second and third places.

Post-Event Materials

Presentations presented at the forum, video recordings of the forum sessions, the Mining Goes Digital conference and business tracks will be published on April 25. Access to the materials will be provided to all delegates of the forum.

About MINEX Kazakhstan forum

MINEX Forum has been organised in Kazakhstan since 2010 and is one of the most representative industry events in the Central Asian region.

More than 300 full-time and over 1,000 remote participants attended MINEX Kazakhstan 2022. During the two days of the Forum, presentations of over 70 experts from Kazakhstan, Russia, Uzbekistan, Kyrgyzstan, Great Britain, Germany, Australia, Canada, the USA, New Zealand, Finland and Spain took place. More than 40 technological and service companies developing projects in Kazakhstan were presented at the exhibition, organized at the forum site.

First Day Overview

On 6 April, Vice Minister of Industry and Infrastructure Development of the Republic of Kazakhstan Ruslan Baimishev and Ambassador of Her Majesty the Queen of Great Britain Katie Leach made welcoming speeches to the participants.

First session

The Forum began with a plenary session under the general theme “New impetus for the development of metals and mining in Kazakhstan. Expert Panel“. In the first part of the session, experts discussed the bug challenges for the mining and metallurgical industry of Kazakhstan and possible solutions.

The discussion was attended by Ruslan Baimishev – Vice Minister of Industry and Infrastructure Development of the Republic of Kazakhstan, Nikolay Radostovets – Executive Director of the Republican Association of Mining and Metallurgical Enterprises, Diyar Ereshev – Member of the Working Group on the Development of the Subsoil Code, Kazakhstan Bar Association, Almat Daumov – Partner of GRATA International and Zarina Baikenzhina – Senior Associate Holler Lomax.

The following topics were highlighted at the session:

- Increasing financial burden on the MMC (cost growth, industrial inflation; increase in mineral extraction tax rates and the introduction of OPVR – from 2023; obligations to introduce BAT, or an increase in environmental payments – from 2025; the introduction of the EU “carbon tax” – from 2026).

- Deterioration of the quality of the mineral resource base (exhaustion of reserves of rich deposits, low replenishment rate, lack of flexibility in the taxation system).

- The necessary transformation of the coal industry (production of products from coal with high added value, development of exports, introduction of promising coal combustion technologies, “socially fair” energy transition).

During the discussion, experts proposed possible ways to solve problems related to administrative and tax management issues in the field of subsoil use.

Problem. Land disputes of subsoil users during the transition to the production stage are associated with the inaction of Akimats and, as a result, put the “exclusive right to production” at risk.

Decision. As a possible solution, it was proposed to provide for the right of the local executive body to seize land for state needs in subsoil plots for mining.

Problem. The principle of “one mining license – one subsoil plot” has created problems of administration (separate accounting, mining plan, liquidation plan, etc.).

Decision. To solve the problem, it is necessary to provide for the possibility of having several TPI production sites under one mining license if they are part of the same field.

Problem. The increase in the severance tax rates and the abolition of the dividend tax and growth tax exemption for projects with deep processing of the TPI require a more detailed study of the impact of the mineral extraction tax rates on the rational and integrated development of subsoil.

Decision. Experts consider it necessary to work out the Rules for classifying TPI fields as low-margin, as well as to resolve the issue of maintaining benefits for deep processing.

Problem. Liquidation Insurance: Often the costs exceed the EMR for exploration operations.

Decision. Annual insurance and binding to the content of the exploration plan.

After the discussion part, Serik Urbisinov, Chief Resource Geologist, CSA Global (a company of the ERM group) made a presentation ” KAZRC: Why codes are integral to attracting global mining investment in Kazakhstan”. Colin Hay, Executive Vice President, EMEA, Seequent spoke about the potential opportunities and benefits of digital transformation in geological exploration in Kazakhstan. The session was concluded by Roman Mezhuev, CEO, BrainHunt, who made an overview report on the topic ” Labor Market in the Mining Industry of the Republic of Kazakhstan”.

Second session

After the break, the forum continued its work with a session on the topic “Development of promising mineral projects with the participation of national and international companies“. The participants of the session were introduced by its moderator – Said Sultanov, Partner of the service geological exploration company Aurora Minerals Group. The session was opened by Talgat Satiyev, Chairman of the Geology Committee, Ministry of Ecology, Geology and Natural resources of the Republic of Kazakhstan with the report “On the development of the geological industry of Kazakhstan”,

At the moment, Kazakhstan is actively discussing the issue of creating the National Geological Service on the basis of the National Geological Exploration Company “Kazgeologiya” and the Republican Center for Geological Information “Kazgeoinform”. The activities and development plans of these organizations were presented at the session by the Chief Geologist of the ” Qazgeology ” Berikbol Khamzin and the General Director of “Kazgeoinform” Zhanat Karibayev.

Kazakhstan is the world’s 5th largest producer of lithium with proven reserves of 50,000 tons and new large deposits under development. Anna Fardell, Senior Resource Geologist, SRK Consulting (Kazakhstan), told the participants about the prospects for the development of lithium potential in Kazakhstan.

Geological prospecting studies are associated with high risks. Discovering a world-class deposit is a rare stroke of luck. Alex Walker, CEO of the British junior company East Star Resources, is engaged in the search for new deposits of gold, copper, and non-ferrous metals in Kazakhstan. The company expects success thanks to a professional team with successful experience in almost all corners of the planet, innovative technologies and, of course, geological success.

Oleg Telnoy, Business Development Director of another British company, Central Asia Metals, spoke about the sustainable and responsible production of copper in Kazakhstan to provide value to all stakeholders. The company plans to expand its business in Kazakhstan and is actively looking for new investment projects.

Kazakhstan private investment company Recourses Capital Group considers geology exploration as a tool for value creation. Nariman Absametov, Investment director, spoke about the company’s experience in creating the value of search projects and managing investment risks characteristic of Kazakhstan.

Uzbekistan is the world leader in gold mining. According to Kitco’s estimate in 2020, the Uzbek mining complex of Muruntau produced more than 2 million ounces of gold. The resource base of Muruntau is estimated at 150 million ounces, which at the current production rate will ensure gold mining for 70 to 80 years. In addition to existing deposits, Uzbekistan has a high mineral resource potential. Strategies for the development of geological exploration in the Republic of Uzbekistan for the long term were presented at the session by the Director of the State Institution “Institute of Mineral Resources” Azimjon Holikov.

Third session

The third session was held under the theme ” Carbon neutrality strategies“. The mining and metallurgical industry is one of the three largest air pollutants. If Kazakhstan fails to meet its obligations to reduce greenhouse gas emissions, companies may lose their positions in the world market due to non-compliance with “green” standards. Achieving the goal of reducing industrial carbon emissions by 19% by 2030 and carbon neutrality by 2060 will require a clear action plan and coordination. To fulfill their obligations, industries need to significantly increase investment in the development of “green” technologies. Many companies are developing plans to drastically reduce carbon emissions. However, the transition to carbon neutrality will require huge investments in new production and energy technologies.

The session was opened Victor Kovalenko, Partner and Head of Climate Change and Sustainable Development Services Practice Ernst & Young – Consulting Services.

In his speech, he presented a problematic report on the topic “Kazakhstan’s Mining Agenda towards a Zero Carbon Footprint». After him, he performed David Pearce, Managing Director SRK Consulting (Russia) who provided practical examples of problem solutions for decarbonization in the mining industry implemented in the last few years. Then, Francisco Igualada, An International Consultant on the Mining Industry of the World Bank, remotely joined the session. He presented the scenarios for the decarbonization of mining and metallurgical enterprises in the Karaganda and Pavlodar regions and spoke about the opportunities for the development of a new “green economy”. The presentation attempts to shed light on issues related to the challenges of reducing carbon emissions in the mining industry and the fact that decarbonization, if properly planned and well implemented, will lead to greater efficiency in mining. Further, the focus shifted to the issues of setting and fulfilling the goals of scientifically based decarbonization. Christopher O’Brien, Senior Consultant (ESG), SRK Consulting (UK) spoke about modern practices in ESG planning. For many large industries, the transition to carbon neutrality is associated with the use of digital technologies that allow processing and analyzing a huge amount of data coming in real time from sensors, machines, and equipment. Sergey Yelshin, Director of Business Development, Mining and Metallurgy, AVEVA, spoke about the role of industrial digital transformation in reducing the environmental impact of production. At the end of the session, Telman Shuriev, Chief Expert of the Production Department, Kazatomprom presented Plans for decarbonization of production, and Talgat Torebekov, Director of the Department of Environmental Protection, “Eurasian Group” spoke about the implementation of the strategy of sustainable ecologisation of enterprises ERG.

Fourth session

The fourth session was held in the format of a discussion on the trends and prospects of

ESG financing in the mining industry. Achieving carbon neutrality in industrial production requires significant costs both on the part of companies and financial institutions, as well as the state. To stimulate ESG financing, incentives and other instruments are being discussed at various levels. Credit institutions and stock markets are developing new criteria. Raising financing for green and adaptation projects helps companies improve ratings and market value. Companies are developing responsible financing tools that allow them to raise funds for the implementation of projects aimed at changing climate impacts and green projects, including waste management, energy, construction, transport, water supply, biodiversity, and environmental protection. In discussion participated Victor Kovalenko,

Partner, Head of Climate Change and Sustainability Services practice, EY; Sergey Sidorkin, Deputy Director along socially-Economic Projects “IMC Montan”; Aidar Kazybayev, Chief Executive Officer, IFC Green Finance Centre, Akop Kagramanyan, Principle Banker Natural Resources, European Bank Reconstruction и Development (EBRD); Jane Joughin, Corporate consultant (ESG), SRK Consulting (UK); Georgiy Freiman, Chairman, Public Union Independent Experts Bowels (PONEN); Katya Gorbatyuk, Primary Capital Markets – CIS & Central Asia, Sustainable Finance Committee and Asem Kernebayeva, Manager director – Chief Directorate along Green и Social Initiatives, Eurasian Development Bank.

Fifth session

The final session of the first day of the forum was devoted to the issues of closure of deposits and reclamation of lands and waters. the Session was held with the support of SRK Consulting (Kazakhstan).

According to official data, about 8 thousand fields operate in Kazakhstan today, all of them were discovered in the years of the USSR. But many of the deposits of lead, copper and a number of rare metals are on the verge of depletion and in 10-15 years will be produced. The closure of the fields is associated with operational and social challenges. Following the depletion of minerals and metals, mining companies are responsible for the reclamation of land and water resources, focusing on environmental issues such as biodiversity conservation and restoration of pre-existing ecosystems. This is a technologically complex and expensive process that is usually taken into account in the early stages of mine design and development. The process of closure of deposits in Kazakhstan began relatively recently and practical experience in solving problems is critical to ensuring the sustainable development of the mining industry. In the East Kazakhstan and Karaganda regions, mass closures of city-forming deposits have already begun. It is assumed that in 5-20 years a number of other fields in the east of Kazakhstan will be closed. The closure of enterprises will lead to socio-economic problems that need to be urgently addressed.

Mike Beare, Director and Corporate Consultant (Mining), SRK Consulting (Kazakhstan), took part in the discussion of the problems of transition to new requirements for the closure of deposits; Sandugash Abdizhalelova, Consultant Ecologist, SRK Consulting (Kazakhstan) and Nikolai Kirillov, Senior Environmental Consultant, SRK Consulting (Kazakhstan).

Then there was a presentation of technological solutions successfully used in the closure of spent fields in Kazakhstan, European countries, and South Africa. Eleanor Widzik-Capehart, Associate Professor, Nazarbayev University spoke about the use of new wireless smart sensors to measure ground movement in quarries and underground mines. Eugene Louppov, Regional Director, Insight Terra presented the experience of monitoring decommissioned tailings ponds. The session was concluded by François du Toit, Consultant Geotechnical Engineer, SRK Consulting (Kazakhstan) with a presentation “TSF monitoring as an assistant in the development of TARP for closure”.

Business Track

In parallel with the forum, a business track was held at the exhibition site on the topic “Technological solutions to improve the efficiency of mining and geological prospecting operations”. It presented modern geophysical equipment of the company GEODEVICE; innovative drilling tools of “MUD MASTER”; Geophysical survey technologies of Geoscan; Mineral targeting and certification of SRK Exploration Services results; Automation of geological exploration operations using MEFFA Lab handheld analyzers; Inflatable packers for hydrogeological works in Exostra wells; Engineered Solutions “Colid Drilling Solutions Qazaqstan”; Casesthem Lab “Stuart Essays End Environmental Laborathoris“, Modern Strategies for Ore Prospecting “GM Service”; Technologies of strengthening weak soils of AsiaGeoCenter-kz and Electric Heating Systems of nVent Thermal KZ.

About MINEX Kazakhstan forum

The MINEX Forum has been organised in Kazakhstan since 2010 and is one of the most significant industry events in the Central Asian region. The last time MINEX Kazakhstan forum was held in a physical format in 2019. It brought together more than 450 executives from 16 countries representing 152 companies and organisations. More than 600 people attended the trade show, and more than 80 experts presented at the Forum. In March 2021, a virtual 3D exhibition was launched on the digital platform of the Forum, creating unique presentation and communication capabilities in an interactive format using virtual reality and artificial intelligence technologies. In September 2021, the 11th MINEX Kazakhstan forum was held online. The Forum has gathered remotely more than 700 participants from Kazakhstan and overseas.

In the upcoming on 6 – 7 April MINEX Kazakhstan 2022 Forum, over 300 in-person and over 1,000 remote participants are expected. During the two days of the Forum, there are planned over 70 presentations from experts from Kazakhstan, Russia, Uzbekistan, Kyrgyzstan, Great Britain, Germany, Australia, Finland, Canada, USA, New Zealand and Spain.

A broad discussion of the challenges, trends, and initiatives in the mining and geological industry is organised at the Forum. Heads and experts from Ministries and companies will discuss actions taken by the government and businesses to strengthen Kazakhstan’s capacity to implement strategic development priorities and increase the country’s participation in the global production on critical raw materials.

Main topics of the Forum

- Development of mineral resource potential

- Exploration – Resources for Growth and Efficiency

- Decarbonisation and carbon neutrality

- Technological transformation and digitalisation

- Mining Sustainability Development Programs

- Technological and social aspects of field closures

- ESG investments and financing in the mining industry

The Forum’s agenda is published on the minexkazakhstan.com website.

The Forum will include a discission on new mining investment opportunities in Kazakhstan and Central Asia countries. With the participation of national and international companies, stock exchanges and institutional investors, a discussion will be held on the prospects for organising financing and attracting investments in projects related to subsoil use and achieving carbon neutrality.

At the technical sessions of the Forum, projects and cases of creating digital twins of deposits, the transition to renewable energy sources, decarbonisation of production, environmental monitoring and industrial safety, financing of ESG projects, closure of deposits and reclamation of subsoil use facilities, etc. will be presented.

Exhibition

One of the crucial components of the Forum is the presentation of innovative technologies and subsoil use practices. At the exhibition, organised alongside the Forum, a presentation of more than 40 international technology and service companies developing projects in Kazakhstan will take place. During the two days of the exhibition, 16 companies from Kazakhstan, Russia, Great Britain and Canada will present at the Business Tracks sessions.

Competition

The digitalisation of industrial production is one of the priorities of Kazakhstan’s economic development. According to official estimates, the digitalisation of mining production can increase the efficiency of almost all enterprises in the mining and metallurgical industry by 10-15 percent and reduce the cost of mining and transportation operations. At small and medium-sized enterprises, this potential is up to 50% or more. Many enterprises in the mining and metallurgical industry in Kazakhstan have already formed a strategy for the digital transformation of production and are studying the possibilities of introducing Industry 4.0 technologies to improve the efficiency of individual enterprises and large integrated production complexes.

For the first time, a MineDigital – Kazakhstan competition of digital transformation technologies for enterprises in the mining and metallurgical industry is being organised alongside the Forum.

The purpose of the MineDigital competition is to present advanced cases and technologies of digital transformation technologies and assess the potential for their implementation at the mining and metallurgical enterprises in Kazakhstan.

A tailor made digital technology will be used to determine the competition winners. On 7 April, during the sessions of the Mining Goes Digital conference and the Digitalisation Business Track, the Forum participants will be able to vote for the presentations they like most using the algorithm integrated in the Forum mobile application. At the end of the Forum, the algorithm will calculate the voting results, which will be submitted for verification to the competition commission. The winners will be announced on 7 April at the final Gala Dinner of the Forum. Participants of the competition will receive commemorative diplomas. Presentations that receive the maximum votes will be awarded prizes for the first, second and third places.

Brief History of Geologists Day

Geologists Day is a professional holiday of geologists, geophysicists, hydrologists and geochemists. In addition to geologists, many others involved in related fields also consider this day as their professional holiday and celebrate it.

It is traditionally celebrated on the first Sunday of April. The establishment of this holiday was initiated by a group of prominent Soviet geologists headed by academician Alexander Yanshin in 1966 after discovery of the West Siberian petroleum province. The timing of the holiday, the first Sunday in April, was chosen because it marks the end of winter and beginning of preparation for summer field work and expeditions.

Geologists Day is traditionally celebrated in almost all geological and mining organizations of the former Soviet Union with festivities starting at the end of preceding week. With tens of thousands of geologists from the former Soviet Union working around the world, the tradition of celebrating the Geologists Day is becoming more international.

Who are Geologists?

The work of geologists is associated with the search and evaluation of mineral deposits, as well as the study of the structure of the earth’s crust. Geologists take part in exploration expeditions and research projects. Geologists often travel across countries and continents and work in the most remote part of our planet. Geologists’ profession is associated with the spartan ways of life deprived of luxuries and modern conveniences. Their work requires strong physical and mental health. The profession of a geologist appeals to people who like to travel and explore.

What Personal Qualities Do You Need to be a Good Geologist?

To become a good geologist, you need such qualities as observation, the ability to analyse information, physical endurance, a love of life in the nature, a willingness to overcome the difficulties associated travel in unchartered and remote areas. An much, much more…

Test your knowledge and learn curios facts about geology

How old is planet Earth?

Planet Earth is 4.5 billion years old.

What does the word "geology" mean?

Geology literally means “the study of the Earth” in ancient Greek.

When was first geological research party created in Russia?

The first state research and exploration institution in Russia was created by the Order of Mining Affairs signed by Tsar Peter the Great in 1700.

What is the deepest man-made well in the world?

The deepest well in the world is the Kola ultra–deep well. It is located in the Murmansk region. Its depth is 12.26 km. The temperature at the deepest point is 220 °C.

Where are the Gates of Hell?

The Darvaza gas crater (also known as the Door to Hell or Gates of Hell), is a natural gas field collapsed into a cavern near Darvaza, Turkmenistan.

Soviet geologists may have intentionally set it on fire to prevent the spread of methane gas, and it is thought to have been burning continuously since 1971. The gas crater has an area of 5,350 m2. Its diameter is 69 m (226 ft), and its depth is 30 m (98 ft). The surrounding area is also popular for wild desert camping.

Is ice a mineral?

For a substance to be called a mineral, it must meet several requirements: be of natural origin, be inorganic, solid, chemically homogeneous, and be in a crystalline state. Based on this, naturally formed ice is technically a mineral. And, for example, water frozen by a person in the refrigerator cannot be called a mineral.

Why did the most common mineral on our planet was named only in 2014?

The most common mineral on our planet was named only in 2014 — it was called bridgmanite. Previously, it was known as silicic perovskite, but no one could study it, since the deposits of this mineral are located in the lower mantle at a depth of more than 700 km below the Earth’s surface. Scientists are not able to reach this depths, but they discovered a fragment of a mineral in a meteorite, after which they were able to apply for naming it to the International Mineralogical Association. Geologists estimate that bridgmanite makes up 93% of the lower mantle volume, or 51% of the Earth’s volume.

Films about Geologists and Geological Profession

We invite you to watch short documentary films (in Russian) about geologists and geological profession submitted to the MineMovie competitions organised by MINEX Forum in Russia in 2020.

Главный геолог

Папа – геолог

Будни геологов 70-х

Геологи в верховьях Енисея

Пешком по дну океана

Полевые работы геомеханика и гидрогеолога SRK

Знакомство с Тувой

Чистая профессия

MineDigital competition is organised for the first MINEX Kazakhstan Forum. Its objective is to present advanced cases and technologies of digital transformation and evaluate the potential for their implementation at the mining and metallurgical enterprises in Kazakhstan.

Among the participants of the competition are Altynalmas (Kazakhstan), Kazzinc (Kazakhstan), Ust-Kamenogorsk Titanium and Magnesium Plant (Kazakhstan), National Atomic Company Kazatomprom (Kazakhstan), KATKO (Kazakhstan), Two Key (Kazakhstan), AVEVA (UK), Seequent (New Zealand), Synergo Soft Systems (Russia), AG TECH (Kazakhstan), WEIR Motion Metrics (Canada), SightPower (Canada), Intelligent Solutions (Russia), Wonderware Russia & CIS (Russia), Rajant Corporation (USA), MICROMINE (Australia), K-MINE (Ukraine), Conundrum Industrial ( UK), IntelliSense (UK), Datamine (UK), LocoTech-Signal (Russia).

The uniqueness of the competition lies in the fact that the evaluation of presentations will be organised in person and remotely by the participants of the Forum, using a web application developed by the MINEX Forum organisers. Previously, such competitions were evaluated by jury members who did not have the opportunity to receive feedback from the forum participants.

Voting will be organised in real-time on April 7 during the sessions of the Mining Goes Digital conference and the digital business track. The Forum participants will be able to vote for the presentations they like most. During the day, the algorithm will collect and analyze votes. At the end of the day, the results will be submitted for verification to the competition commission.

The announcement of the results of the competition will take place on April 7 at the final session of the Forum.

Participants of the competition will receive commemorative diplomas. Presentations that receive the maximum number of votes will be awarded prizes for the first, second, and third places. The award ceremony will be broadcast live on the Forum’s website.

On Thursday, March 17, we have organised online presentation of the MINEX Kazakhstan 2022 forum where we presented the program of planned events and answered questions. To access the video recording of the presentation, please fill out the form.